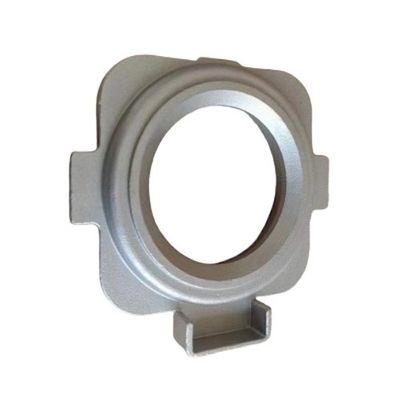

Investment Casting Components Steel Casting Parts For Combine Harvester Parts

Product Details:

| Place of Origin: | China |

| Brand Name: | Twinkle Industrial |

| Certification: | ISO 9001 |

| Model Number: | TISCP-47 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100 pcs |

|---|---|

| Price: | USD 30 ~ 50 per pc |

| Packaging Details: | Non-fumigation wooden box |

| Delivery Time: | 25 work days |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 2000 pc per month |

|

Detail Information |

|||

| Product Name: | OEM 45# Mild Carbon Steel Casting Parts For Engineering Equipments | Dimensions: | Sample Or Drawing |

|---|---|---|---|

| Process: | Investment Casting+machining | Surface Treatment: | Shot Blasting |

| Highlight: | Combine Harvester Steel Casting Parts,Investment Components Steel Casting Parts |

||

Product Description

Investment Casting Components Steel Casting Parts For Combine Harvester Parts

Quick Detail:

· Mild Steel Casting Parts

· Carbon Steel 45#

· Lost Wax Investment Casting + Machining

· Shot Blasting

· Construction Equipment

Product Description:

Combine harvesters, also known as combine harvesters or simply combines, are agricultural machines used for harvesting crops such as wheat, corn, soybeans, and rice. Steel casting parts play a crucial role in the construction and functioning of combine harvesters. Here are some examples of steel casting parts used in combine harvesters:

-

Threshing Cylinders: Threshing cylinders are key components in the harvesting process. They separate the grain from the crop stalks or cobs. Threshing cylinders often contain steel casting components, such as cylinder bars and rasp bars, which are designed to efficiently thresh and separate the grain from the crop material.

-

Concave Grates: Concave grates are positioned beneath the threshing cylinder and help separate the grain from the straw or chaff. These grates often incorporate steel casting parts that provide durability and resistance to wear, as they are subjected to significant friction and impact during operation.

-

Cutting Blades: Combine harvesters include cutting systems to harvest crops efficiently. Steel casting parts, such as sickle sections or cutter blades, are used in the cutting mechanism to slice through the standing crop. These blades need to be sharp, durable, and resistant to wear to ensure efficient cutting performance.

-

Augers and Conveyors: Augers and conveyors are integral parts of the grain handling system in combines. They transport the harvested crop from the cutting mechanism to the threshing and separation components. Steel casting parts may be used in the construction of augers, conveyor flights, and other components to provide strength, rigidity, and durability.

-

Sieves and Shakers: Sieves and shakers are responsible for further separating the grain from the chaff and other debris. Steel casting parts, such as sieve frames and shaker shoes, are used to withstand the vibration and movement involved in the separation process.

-

Chopper Blades: Combine harvesters often feature chopper systems to finely cut and distribute the crop residue after harvesting. Chopper blades, which may include steel casting components, are used to shred the crop material into smaller pieces for more efficient distribution across the field.

-

Separator Grates: Separator grates help separate the grain from the remaining crop material after threshing. These grates may incorporate steel casting parts that provide strength, durability, and efficient separation capabilities.

Product Specifications:

| Commodity | Steel Casting & Machining Parts |

| Standard | ASTM, DIN,JIS, EN, ISO, BS, GB |

| Material | Carbon Steel 45#, Alloy Steel, Stainless Steel 304, 316 |

| Unit Weight | 0.1kg ~ 100kg. |

| Tolerance | CT6 ~ CT8 |

| Machining | Turning, Milling, Drilling, Cutting, Reaming, Threading, Welding, Tooling, etc |

| Surface Treatment | Shot blasting, Painting, Powder coating, Electroplating, Chrome plating, Nickel plating, Mirror polishing, etc. |

| Package | Standard wooden box package or as your customized package |

| Applications | Agricultural machinery, Petroleum machinery, Mining machines, Construction, Automotive & Truck, Medical, Marine, Railway & Train, Power lines, Furniture, Lighting, Valve and Pump, etc. |

| Brand | Twinkle Industrial |

Applications:

Widely used agricultural machinery, petroleum machinery, mining machines, construction, automotive & truck, medical, marine, railway & train, power lines, furniture, lighting, valve and pump, etc.

FAQ

Q1. How can we get a quotation?

A: Please send the parts 2D drawing (in PDF format) and 3D model in IGS or STP format together with material, production technique, purchasing qty, etc, or provide sample to us.

Q2. What about the lead time?

A: 15-20 days for Sample making ,20 working days for mass production.

Q3. Do you have any MOQ limit for casting parts?

A: It depends on different parts. For some parts, 1 pc can be acceptable.

Q4. What is your payment term?

A: Mold: 50% payment in advance, balance after the sample approval.

B: Mass production: 30% payment in advance, 70% balance before shipment.

Q5. What is your quality control process?

A: Each casting parts will be provided with raw material report ( chemical composition and physical property), and dimension measuring report before shipment.

Q6. How about the packaging?

A: Standard wooden box package or as your customized package.