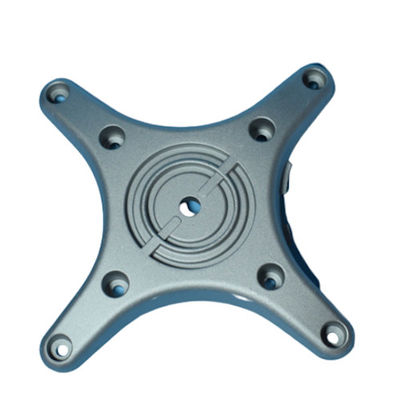

ADC12 Gravity Cast Aluminum Base For Lighting Industry

Product Details:

| Place of Origin: | China |

| Brand Name: | Twinkle Industrial |

| Certification: | ISO 9001 |

| Model Number: | TIMCP-03 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 pcs |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Non-fumigation wooden box |

| Delivery Time: | 20 work days |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 20000 pc per month |

|

Detail Information |

|||

| Product Name: | Aluminum Alloy A356 Gravity Castings Metal Casting Parts For AutomotiveAluminum ADC12 Gravity Casting Base Metal Casting Parts For Lighting Industry | Application: | Lighting Industry |

|---|---|---|---|

| Dimensions: | As Mould | Process: | Metal Gravity Castings |

| Surface Treatment: | Shot Blasting Surface | Tolerance: | As Drawings Tolerance |

| Highlight: | ADC12 Gravity Cast Aluminum Base,Metal Casting Parts Base ADC12,Cast Aluminum Base For Lighting Industry |

||

Product Description

Aluminum ADC12 Gravity Casting Base Metal Casting Parts For Lighting Industry

Quick Detail:

· Metal Gravity Casting Parts

· Aluminum alloy ADC12

· Gravity Casting Production Technique

· Shot Blasting

· Lighting Industry

Product Description:

In the mass production of medium and small castings of non-ferrous metals, as long as the melting point of the casting material is not too high, metal mold casting is generally preferred. However, metal mold casting also has some disadvantages: because heat-resistant alloy steel and the processing of making hollow cavities on it are relatively expensive, the cost of metal molds is expensive, but overall it is cheaper than die-casting molds.

Product Specifications:

| Commodity | Metal Gravity Casting Parts |

| Standard | ASTM, DIN,JIS, EN, ISO, BS, JCSI, GB |

| Material | 1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) Zinc alloy 3#, 5#, 8# |

| Mold Material | SKD61, H13 |

| Tolerance | CT4-CT8 |

| Machining | Turning, Milling, Drilling, Cutting, Reaming, Threading, Welding, Tooling, etc |

| Surface Treatment | Shot blasting, Painting, Polishing, Powder coating, Electroplating, Chrome plating, etc |

| Package | Standard wooden box package or as your customized package |

| Applications | Agricultural machinery, Petroleum machinery, Mining machines, Construction, Automotive & Truck, Medical, Marine, Railway & Train, Power lines, Furniture, Lighting, Flange, Valve and Pump, Electronic, Pipeline, etc. |

| Brand | Twinkle Industrial |

Product Applications:

Widely used agricultural machinery, petroleum machinery, mining machines, construction, automotive & truck, medical, marine, railway & train, power lines, furniture, lighting, flange, valve and pump, electronic, pipeline, etc.

![]()

FAQ

Q1. How can we get a quotation?

A: Please send the parts 2D drawing (in PDF format) and 3D model in IGS or STP format together with material, production technique, purchasing qty, etc, or provide sample to us.

Q2. What about the lead time?

A: 15-20 days for Sample making ,20 working days for mass production.

Q3. Do you have any MOQ limit for casting parts?

A: It depends on different parts. For some parts, 1 pc can be acceptable.

Q4. What is your payment term?

A: Mold: 50% payment in advance, balance after the sample approval.

B: Mass production: 30% payment in advance, 70% balance before shipment.

Q5. What is your quality control process?

A: Each casting parts will be provided with raw material report ( chemical composition and physical property), and dimension measuring report before shipment.

Q6. How about the packaging?

A: Standard wooden box package or as your customized package.